Significance

Workplace safety is the utmost target for operations since unsafe working may cause losses of lives and assets, as well as have an impact on the environment and employee’s health. As a result, creating a safety culture to proactively prevent accidents must be carried out and improved regularly for example, arranging a safe working environment, setting up clear preventive measures, monitoring safety performances, fostering knowledge and raising awareness, as well as drawing participations from all employees and involved parties.

A safe workplace environment is counted as the human rights of which employees, contractors and those entering the areas should get sufficiently and equally. In addition, promoting employee participation in expressing their ideas to improve their workplace conditions will finally help in creating their contributions, encouragements and engagements with the organizations.

Management Approach

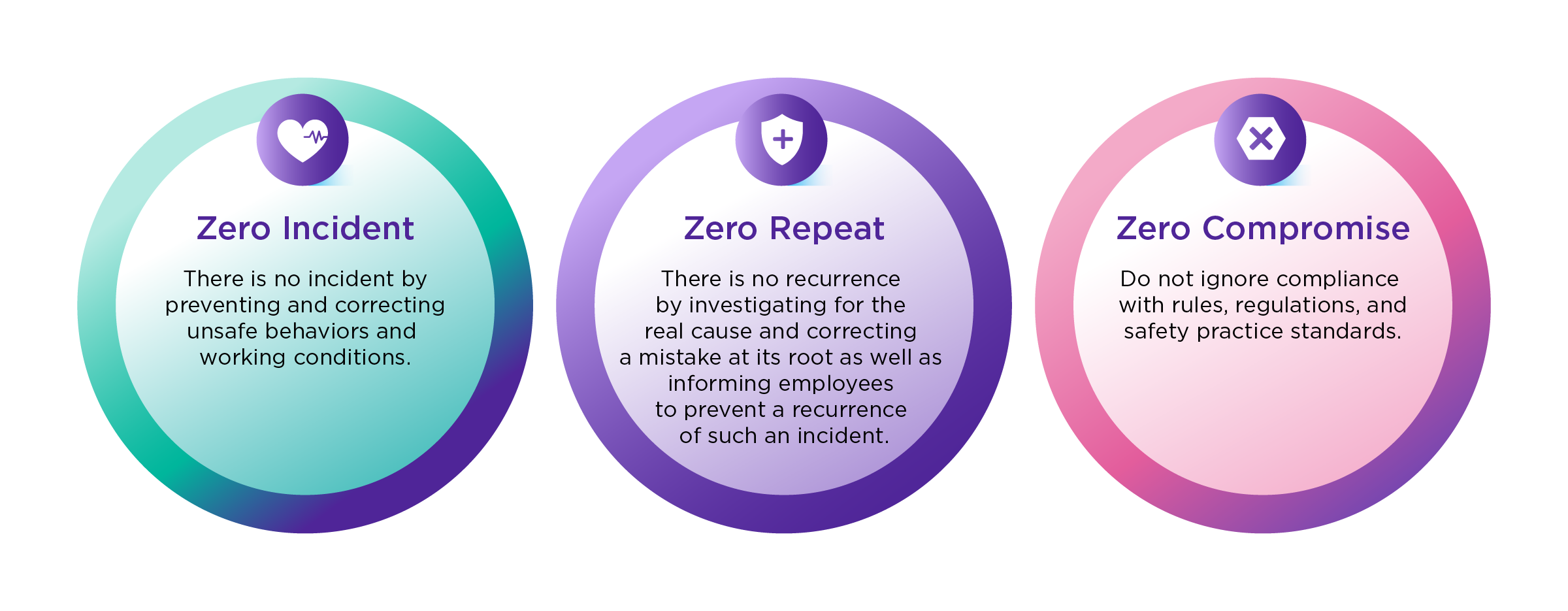

BPP has focused on cultivating a safety culture within the organization with the ‘3 ZEROs’ target as followings:

To achieve the above targets, BPP has managed its safety as following:

Performance

- Zero LTIFR.

- Zero facility case.

Key Activities and Projects

BPP organized the work-safety promotion activities, for example:

- Measuring the workplace environment and making it safe.

- Training and testing on safety and environment, safety rules and risks in the areas prior to working, as well as strictly reviewing them at a defined time.

- Promoting working safety and regularly inspecting a workplace by top management.

- Conducting safety inspections carried out by employees, supervisors and safety officers during operations.

- Setting up the safety improvement committee for offices and power plants.

- Communicating with involved parties to raise safety awareness through various activities, such as emails games and posters, etc.

- Exercising the emergency plans by simulating various scenarios regularly.

- Providing incentives for safe working, such as special rewards for contractors having outstanding safety practices, celebrations on common achievements, etc.

BPP has provided the health promotions for its employees such as:

- Arranging a health check-up for employees in accordance with the COVID-19 epidemic preventive measure strictly, providing health insurance for COVID-19 treatment and coordinating on the provision of vaccines for employees.

- Organizing an annual health check-up and a physical fitness measurement for employees based on risks arising from the nature of work.

- Inspecting working environment in both offices and production units, and improving, as well as standardizing working conditions continuously.

- Encouraging employees to exercise and maintain good health, such as establishing sports clubs, providing health related knowledge, including arranging an individual exercise trainer for interested personnel etc.

- Arranging a psychological consultation project called “iSTRONG” for employees, allowing them to consult with psychologists regarding mental matters to reduce stresses from personal life and work. All information consulted will be kept confidential by an external psychological service provider.

- Establishing an online doctor visit project for employees. The project has been executed since the COVID-19 pandemic up to present. Through the online doctor, employees can make an appointment and have a preliminary check with the doctor

online. Then, the doctor will quickly prescribe the medication and deliver it to that staff. - The Flexible Benefit project was created to support an annual budget of THB 12,000 for employees to use in various benefits inclusion of health, such as expenses for additional medical treatment, sports club membership fees and devices to facilitate

ergonomic working from home, etc.

Located in Shijiazhuang City, Zhengding County, Hebei Province, People’s Republic of China, Zhengding CHP Plant has a total installed capacity of 139 MWs and produces approximately 10 million Gigajoules (GJ) of heat per year, contributed for users in Zhengding County where around 58,000 residents and more than 180 of the industrial sector, trades and others are living. It is the only power plant producing heat supplied for a centralized heating system in the area, which is essential to residents during winter when the average outdoor temperatures are around 0.3 Celsius.

Zhengding Power Plant has tried to stabilize its heat transmissions and improve the safety by installing equipment and establishing a real-time remoted monitoring system applied to the heat exchange station in order to replace staff visits to the station area, reducing risks and operating times from entering the station zone. More importantly, it has made it possible to quickly detect abnormalities so that they can be corrected immediately, including increasing the power plant’s stability of heat supplies.

The installation of intelligent thermal inspection and control equipment includes:

- Remotely inspecting via video cameras

- Remotely controlling and adjusting the water pump’s recirculation frequencies.

- Remotely controlling and adjusting the steam and hot water flows intensity in the heat exchanger station.

- Employing the information collection system related to pressures and temperatures from various devices in the system such as water pumps, pressure regulator valves, water tanks, etc.

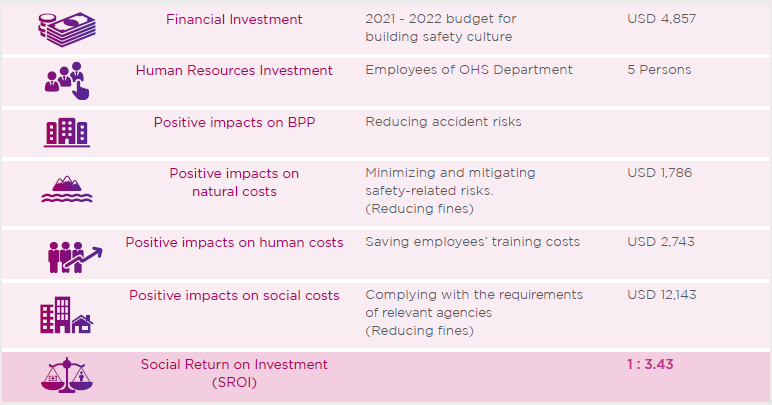

This project implementation has enabled Zhengding CHP Plant to reduce the number of employees inspecting the heat exchanger station from 200 persons to 40 persons, reducing the employee safety risks derived from being exposed to noises and heats and the electricity costs by 18.4%, or CNY 864,000 per annum. When assessing this project’s safety with the Social Return on Investment (SROI), the project has generated values of approximately CNY 5.67 million.

In addition, Zhengding CHP Plant has also upgraded its heating equipment to accommodate thermal generations in accordance with the growing populations in Zhengding County. The plant has also improved its equipment inspections, including developing and exercising the emergency plans. As a result, the plant has been certified by the ISO 45001 Occupational Health and Safety Management System continuously. This has made the power plant to operate stably and safely. There were no working accidents while the availability factor was maintained at a high level of 94.04%. More importantly, the power plant was bestowed the Advanced Unit of Central Heating award from the government sector.

Typically, a power plant needs to be planned for maintenance so that the machines can continue operating. The maintenance planning is conducted by the maintenance department, which will proceed the documentations specifying work details, persons working in the area, operational periods and risk assessments to the production department to consider and cut off some working systems so as for safe operations of the maintenance department.

However, there are too many of such documents, which must be sent to different departments for inspections, such as the production and safety units, etc. This has resulted in document losses during operations. Additionally, these documents must be used together by many parties, making it inconvenient and difficult to access risk details of each maintenance. Or if the document is lost, it will not be able to trace back.

Luannan CHP Plant, therefore, has developed the Double Control application to replace all documental operations. In the form of digital, the Double Control application allows relevant parties to create documents requested for approval, giving approval and checking the data simultaneously. It also prevents document losses, making maintenance operations go smoothly while operators stay safe from working. Around 50% of time was also saved. When assessing this project result relating to safety with the Social Return on Investment (SROI) tool, the value of about CNY 104,800 was estimated from this project. The value was gauged from time-saving, enhancing employee’s knowledge, keeping documents for legal retrospection and securities arisen from using this application This was exclusive of the value from project expansion to other BPP’s power plants.

In the past year, Luannan CHP Plant had no major working accidents and has consistently accredited by the Occupational Health and Safety Management System (ISO 45001). Moreover, the plant was selected as the outstanding occupational health enterprises. It was awarded as the outstanding prefectural workers’ vanguard from the government sector as well.

To prevent accidents possibly occurring during unloading coal from the vessels, BLCP Power Plant has applied the AI Vision to detect and alert contractors and employees when they are operating on coal vessels and bulldozers, which have limited visibility and environmental conditions, such as field of vision, hearing noises, etc. Using the AI Vision will help in identifying the characteristics of people and machines, safe operating distances as well as immediately alerting the operators when the distance between the local operator and the machine is closer than the safe distance. This can significantly reduce the risks involved with working accidents.

The Occupational Health and Safety Department has initiated and driven the concept of creating safety culture. This has resulted in a positive impact on employee’s safety. A higher level of safety culture reduces unsafe actions – the main cause of accidents. More importantly, a strong safety culture helps keep employees safer, have a good level of safety performance, reduce accidents and mitigate risks appropriately.

BPP has applied this safety culture at its solar power plants, namely Haoyuan, Xingyu and Jixin, totaling 7 locations. The safety culture cultivation of these power plants started with the top executive of solar power plants transferring knowledge and promoting a culture of safety by himself. This has been run through participating in site visits, conducting safety inspections, communicating safety information, and showing commitments to safety operations. In addition, the safety meetings coupled with safety trainings are organized on a monthly basis. Meanwhile, safety documentation is provided and communicated to employees. As a result, the safety performance of these solar power plants has been improved, while the number of incidents related to chemicals has decreased significantly.

Since 2018, BPP has continuously evaluated the excellence level of safety culture, by using a survey based on the United Kingdom Health and Safety Executive (UK HSE) Safety Culture Maturity model, which divides safety culture into five levels:

An action plan will be created after receiving the survey results so as to improve the safety culture, such as drawing more participation from executives, creating new work procedures, preparing appropriate personal protective equipment and training.

In 2023, Luannan and Zouping CHP plants reassessed the excellence level of their safety culture after the latest assessment in 2019. The two CHP plants’ assessment results were at the “Co-operating” level. Meanwhile, Deyuan Solar Power Plant was assessed at its safety excellence

level for the first time, with the “Involving” level. Moreover, five activities can be improved as follows:

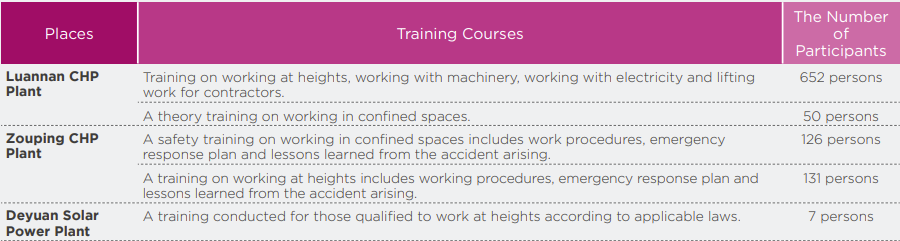

1. Working according to risks, such as working in confined spaces. As a result, a training was arranged, including improving gas leak detection equipment, providing correct personal protective equipment and exercising emergency drills.

2. Working at height: Providing training according to applicable laws, preparing appropriate personal protective equipment, including organizing relevant training courses for employees and contractors. The power plants achieved the targets 100%, which were in accordance with the plan set as follows:

3. Improving the working areas to be clean and safe, including creating measures to reduce danger risks, such as displaying appropriate warning signs, fixing and repairing damaged equipment.

4. Selecting appropriate personal protective equipment for working at heights and working with electricity.

5. Improving work procedures for contractor management, creating training plans according to job positions, upgrading procedures for specific tasks, such as heat-related work at Luannan CHP Plant.

Assessing the excellence level of safety culture to identify opportunities for safety improvement has contributed to enhancing abilities and creating safety awareness among employees and contractors, as well as significantly reducing unsafe working behaviors.

Document Download

Occupational Health and Safety Policy