Significance

The major costs of thermal power plants and combined heat and power (CHP) plants are from fuels used for generating power, steam and other forms of energies. The energy consumption efficiency, therefore, directly affects costs and competitive advantages as well as greenhouse gas emissions. Meanwhile, the regulations specifying the amount of coal consumption in China have been the challenge, BPP has to adjust itself to cope with such changes. These include improving the energy consumption of existing power plants and developing the future power projects to have lower energy consumption intensity as well as to be part of alleviating the climate change.

Activities involved with energy consumption in generating power, steam and heat include:

- Using coal as a fuel for productions.

- Using diesels to ignite the boilers and as a fuel for heavy equipment and transportations.

- Using gasolines and diesels for transportations.

- Using other fuels for productions such as waste gases from the blast furnace gas industry.

- Purchasing electricity from external sources.

Management Approach

BPP has focused on providing energy management services for the maximum efficiency, namely:

- Selecting the high-performance technology with minimal fuel consumptions and environmentally friendly.

- Improving the boiler efficiency to have the most complete combustion.

- Planning for efficient maintenances to increase the power plants’ availability factor (AF), reducing the planned outage factor and the unplanned outage factor, as well as lessening energy losses from stopping running and starting operating the machine.

- Looking for opportunities to lower heat and power losses in the system and reuse it.

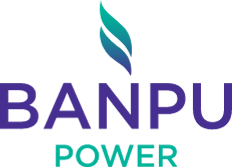

- Improving other supportive systems such as upgrading water quality inside the boiler for longer use, reducing water discharges and filling up new water to the system.

- Seeking opportunities for using more energy sources in the area such as waste gases from the blast furnace gas industry, natural gases, biomass fuels, etc.

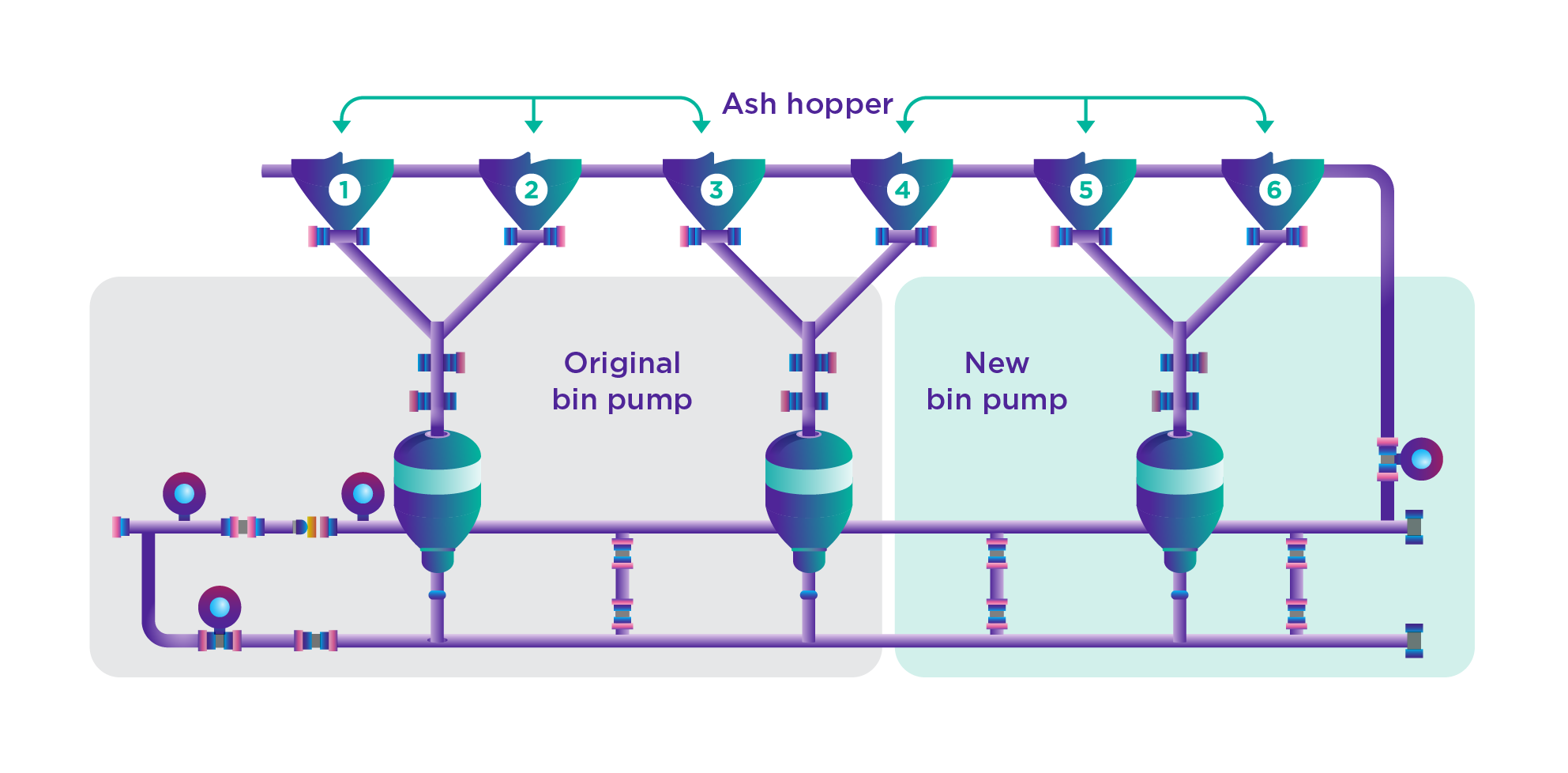

- Planning to purchase multiple fuels from various sources in order to manage the fuel supply with high quality and reasonable prices and to reduce any risks associated with fuel shortages.

- Developing the integrated energy management applications for power plants, starting from purchasing, storage, and blending to production’s combustion process.

Performance

- The energy consumption intensity was 2.30 GJ/MWh.

– Combined heat and power plants’ energy consumption intensity of 0.82 GJ/MWh.

– Gas-fired power plants’ energy consumption intensity of 3.92 GJ/MWh

Key Activities and Projects