Significance

BPP has pursued the “Greener & Smarter” strategy corresponding to the transition towards more clean energy generation in the future. This includes a more efficient energy consumption model deprived from development of various energy technologies. Consequently, BPP focuses on investments creating growths from thermal power production, by using clean and high efficiency with eco-friendly technology, coupled with expanding electricity generation to renewable energy, energy technology, and smart energy utilization. Furthermore, BPP has put top priority on continuous improvement to heighten its power plant’s reliability and efficiency, with high availability and low forced outage factor. Besides, it also focuses on creating competitive advantages in response to an increase in the electricity free-trading market in the future. This is to deliver various forms of power and energy contributed to economic and social development during the transition of energy consumption patterns in the society, making it moved smoothly.

Management Approach

- Production

BPP focuses on creating stability and improving the power plants’ efficiency to continually deliver energy to customers, by strictly operating productions according to operating processes. This includes keeping maintenances with quality in line with specified standards, and defining criteria for supervisions, surveillances, audits, risk assessments, as well as regularly monitoring the power plants’ operating performances. It also puts top priority to supply chain management so that fuels and raw materials can be supplied to the production line according to the action plan set.

BPP employs the quality, occupational health, safety, and environment management standards in all of its CHP plants to operate their productions according to the entire operating processes. It also promotes the application of innovation, particularly the digital technology, which can be widely adopted to measurements of various parameters associated with production. That information will be later utilized for creating the production’s availability and stability.

BPP communicates its production and machinery maintenance plans with customers, partners, and contractors in advance to create effective collaboration, which is important in maintaining the power plants’ availability factor (AF) and stability. The annual machinery maintenance is the main activity, making the engine’s conditions efficient with a long-service life. Therefore, the machines can be operated continuously according to customer’s needs and the plans set.

Machinery maintenance of thermal power plants is carried out in accordance with the maintenance standards set for each power plant. The standards include selecting skilled-maintenance contractors, and evaluating their performances for improvement. Each year, the power plants choose to perform their maintenance during the times when there is less energy demand in the area. The aim is to prepare machines before entering into the period of high energy demand. For example, all power plants avoid conducting maintenances simultaneously across all production units because they still have to supply electricity and steam to customers even during their maintenance periods.

- Expansion of Production Capacity and Investments

BPP puts great attention on investing in the power plants equipped with “High Efficiency, Low Emission (HELE) technology according to the “Greener & Smarter” strategy, such as the gas-fired power plants, the renewable energy power plants, the energy technology, and the smart energy solutions. These investments made are in the forms of both business operations with direct management control, and joint – venture companies. Prior to investing, each project must be thoroughly considered on both risks and return on vestments, including examining the project’s environmental, social and governance (ESG) factors. Additionally, the variants associated with ESG issues, such as carbon prices, greenhouse gas (GHG) emissions intensity, and etc. are taken into consideration for each investment to ensure that BPP invests in the businesses able to grow sustainably. Meanwhile, risks are mitigated to an acceptable level. In addition, the thermal power plants currently operating are looking for opportunities to expand their business operations into the integrated energy services to meet the rising demand for clean energy.

Performance

- Commercial operating power generation capacity of 3,642 MW, consisting of:

- 3,247 MWe from thermal power.

- 395 MWe from renewable energy.

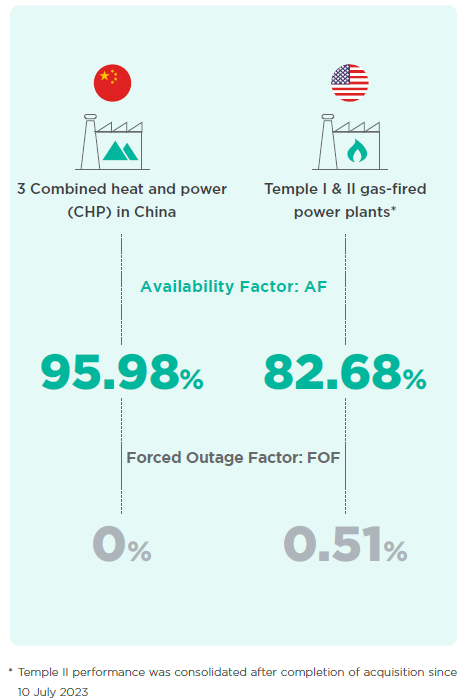

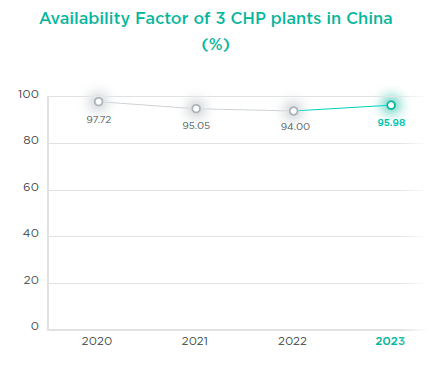

- The AF and FOF of combined heat and power (CHP) plants were 95.98%, and 0%, respectively.

- The AF and FOF of gas-fired power plants were 82.68%, and 0.51%, respectively.