Significance

The climate change impact is an important issue making the situation related to water risks become more severe in the future since water is a main driver for thermal power plants’ production processes, such as generating steam in a boiler, controlling temperatures in a cooling system, including air quality, and etc. Hence, the efficient management of water resources used in the production process and discharged water, both qualitatively and quantitatively, will help lessen the impacts on communities from limited freshwater resources, and from water quality problems possibly affect the environment. It also mitigates BPP’s risks associated with production costs, compliance with applicable laws, and community relations.

Management Approach

To ensure that its operations comply with good operating standards and meet the water quality requirements of each country, BPP has set a water use intensity in the production process and monitored performance against the annual targets. In addition, BPP has created a water system concept model for every power plant to be used for monitoring and managing water resources in a transparent and efficient manner. Thereby, the Water Management Hierarchy approach is used in managing water to achieve maximum benefit, as follows:

- Elimination: Cutting off water use in certain processes, which is considered as the first option if possible.

- Reduction: Taking action or trying to reduce water use in the process when water consumption cannot be eliminated.

- Direct reuse/outsourcing: Using water in many processes without going through a treatment process/purchasing water from outside manufacturers.

- Regeneration reuse/recycling: Water will go through a treatment process before being reused or recycled.

- Fresh water: Consider using fresh water when wastewater cannot be reused or recycled.

Since China’s CHP plants’ water sources for steam generation systems are from ground water and water supplied by external manufacturers, the water management is focused on recycling water as much as possible to reduce the amount of discharged water with quality complying with applicable laws. On the other hand, the gas-fired power plant in United States of America, uses water only from external producers supplying used water from the community to the power plant. In addition, large water storage ponds are in the power plants’ areas to treat and reuse water. Water is treated by using biological treatment methods, controlling the amount of algae and acidity-alkalinity, significantly helping reduce the amount of chemicals used in water treatment. This is to prepare water quality before entering the “Zero-Liquid Discharge” treatment system, making the water quality meet standards and be used in the power plant’s production processes. Such holistic water management makes the power plant have sufficient water reserves and do not release wastewater generated from their production into nearby natural water sources anymore.

To ensure that the water management is implemented while the released water quality is in accordance with applicable laws, BPP measures its water quality before being discharged to outside. The water quality measurement is conducted by BPP and external agencies. However, the types of pollutants measured, the frequency and measurement methodologies of each business unit may differ according to the requirements of each project and as required by laws in each area. Measures are in place to prevent chemical leakage and contamination at the original source. In addition, measures and procedures are determined in the event of any emergency so as to reduce impacts likely arising in the event of an incident regarding water resources and to be able to rehabilitate effectively in an appropriate time.

BPP reviews its assessment of water-related risks and impacts on an annual basis in order to understand water risks and impacts, such as risks related to water shortages, drought, and laws, etc. Moreover, the measures are prepared to mitigate risks and various inspections. The assessment is made by using the water risk map (Aqueduct) of the World Resources Institute (WRI).

BPP has integrated the power plants’ water risk assessment results into the organization’s risk assessment. The risk management measures are as follows:

| Topics | Risks Management Measures |

| Dependency-related water risks considered in risk assessment |

|

| Impact-related water risks considered in risk assessment. |

|

| Assessment of future water quantities available. |

|

| Assessment of future water quality related risks |

|

| Assessment of impacts on local stakeholders. |

|

| Assessment of future potential regulatory changes at a local level |

|

For BPP’s performance measurement, the business water use data is collected according to the GRI 303 (2018) standards to provide information for water management. The water drawn from water sources consists of the amount of surface water pumped from water sources, the amount of groundwater pumped for use, and the amount of water supplied by external agencies. This does not include the amount of rainfall in the area since BPP doesn’t use such precipitation. The data collected are based upon the assumption that local water reservoirs have a minimal capacity, when compared with the water amount drawn from all water sources. For all data of water amount are collected from water meters.

Performance

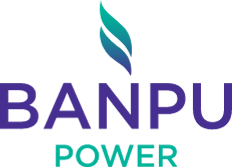

- Water consumption intensity per unit of products was 0.817 cubic meters/MWh.

- Combine heat and power plants 0.717 cubic meters/MWh

- Gas-fired power plants 0.897 cubic meters/MWh

- The quality of discharged water met the standards set by applicable laws.

Key Activities and Projects

Water Risks Assessment

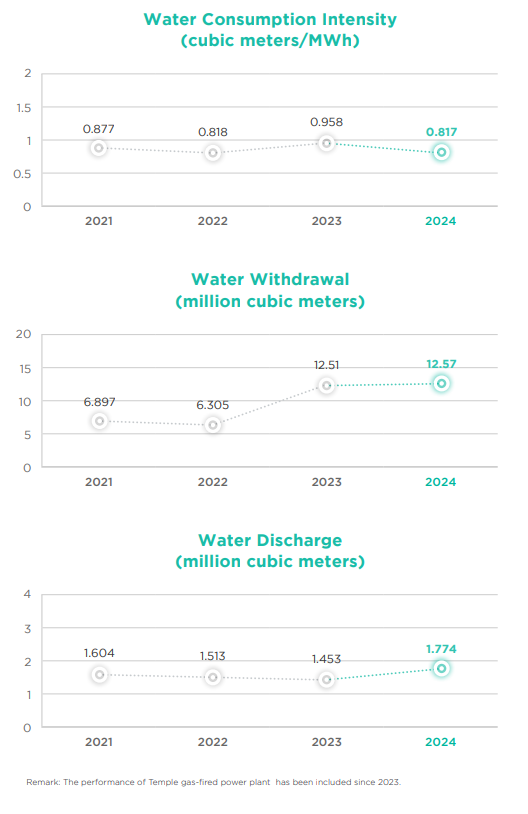

BPP annually assesses water-related risks from all locations of its thermal power plants due to their high demand for water in the production process. BPP uses the “WRI Aqueduct Water Risk Atlas (Aqueduct 4.0)” – a program demonstrating categories of areas with water resource risks, in terms of physical, quantity and quality, regulatory & reputational risks, as well as anticipating future risks, as a reference to assess its water-related risks.

The 2024 assessment, using data on areas currently faced with water shortage risk, and the year 2030 forecast, found that the water-related risks are unchanged from the previous year’s assessment. The assessment results and risk management measures can be summarized as follows:

- The CHP plants in China, namely Luannan, Zhengding, and Zouping, in which BPP has direct control are located in the areas with extremely-high risks associated with water resources. Therefore, the power plants have made improvements to reduce the amount of water consumption and water discharges to comply with the government’s regulations. Meanwhile, the power plant’s extensions have also installed a recycling system in order to reuse all of their released water.

- Temple Gas-fired Power Plant in United States of America, in which BPP has direct control has a low to medium water resource risk, while its risk related to water shortages is relatively medium to high. The power plant has installed a water recycling system. As a result, it is able to reduce water consumption in the area with no discharged water.

- According to the joint-venture thermal power plants, namely BLCP Power Plant in Thailand and HPC Power Plant in Lao PDR, it was found that BLCP Power Plant has high risk associated with water scarcity since the plant is located on the sea. BLCP Power Plant, therefore, has invested in a construction of the desalination plant, producing fresh water and tap water from seawater through the reverse osmosis seawater desalination plant, with a capacity of 1,000 cubic meters/day. The aim is to alleviate the water shortage crisis in the eastern region by producing sufficient water for the people and farmers. Since 2020, the desalination plant has helped in reducing the total amount of fresh water consumed in the area 100%. HPC Power Plant, though, having low risks related to water shortage, the power plant has managed water sources in the area, namely Nam Leuk and Nam Khan water sources. In addition, the power plant in collaboration with the experts conducted a study on using models to forecast water balances in the areas, set up indicators for measuring water quantities in various points for surveillance and determining appropriate measures. The clarifier ponds were constructed within the area to control water quality and to recycle water discharges.

Improving Water Consumption Intensity and Heat Loss Rate of Zhengding Power Plant

The legal enforcement on using groundwater in the Chinese industrial sector has made Zhengding CHP Plant change its water use from groundwater to surface runoff. This has directly resulted in an increase in water costs by approximately 2 times.

Zhengding CHP Power Plant, however, has seen an opportunity to reduce water consumption and lost heat in the system to increase operational efficiency and reduce production costs. The power plant has designed and installed pipe and pump systems to circulate water use at its chemical storage plants and cooling towers.

The designed pump installation has resulted in a reduction of water withdrawal from surface water sources by approximately 280,000 tonnes, equivalent to the production costs of around USD 205,000. In addition, the investment costs for heating systems could be reduced by USD 27,453, while the heat loss costs have been decreased by USD 123,536 per year. This project is part of BPP’s project to promote innovation in organizations.

A Water Management System at Temple Gas-fired Power Plant

Temple Gas-fired Power Plant has a 10-acre (approximately 40,000 square meters) water reservoir within the power plant’s area to obtain water recycled from the wastewater treatment plant, serving surrounding communities. This recycled water is the main source of water, reducing wastewater discharges to nearby natural water bodies. It enables the power plant to have enough water for consumption. The cost of recycled water produced is lower than that of groundwater or other water sources.

Temple Gas-fired Power Plant initially treats the water with a biological methodology through raising fish eating plants and algae as food. Thus, these fish raised help to control the number of algae and the acidity and alkalinity of the water. As a result, it can significantly reduce the amount of chemicals used in water treatment. After that, the water treated is fed into the power plant’s Zero-Liquid Discharge (ZLD) treatment system to meet quality standards. It can be used in the production process of Temple Power Plant as well.

Through this holistic water management, Temple Gas-fired Power Plant has sufficient water reserves, and does not discharge its production’s wastewater into the Texas basin.

Benefits gained from the project

- As using biological methods to treat water, Temple I Power Plant can reduce chemical utilization – Sodium Hypochlorite (NaClO) for wastewater treatment, in the amount of 200 tonnes / year, or a cost reduction of approximately USD 48,912.

- Decreasing the amount of wastewater discharges of about 1.95 megalitres / year.

- Reducing the impacts from withdrawing natural water resources in the area.

- Creating a good attitude towards the community.

Document Download

Water Management Policy