Significance

The valuable resources conservation and utilization is the best practice to minimize waste generated from operations as much as possible. The appropriate and efficient waste management can also help lower costs on waste disposals, including reducing impacts on environment and surrounding communities caused by hazardous waste leakages and improper disposal from thermal power plants. In addition to non–hazardous and hazardous waste, there are ash and gypsum created from fuel combustions and air quality treatment processes, which can be utilized and added value by selling them as mixtures of construction materials.

Management Approach

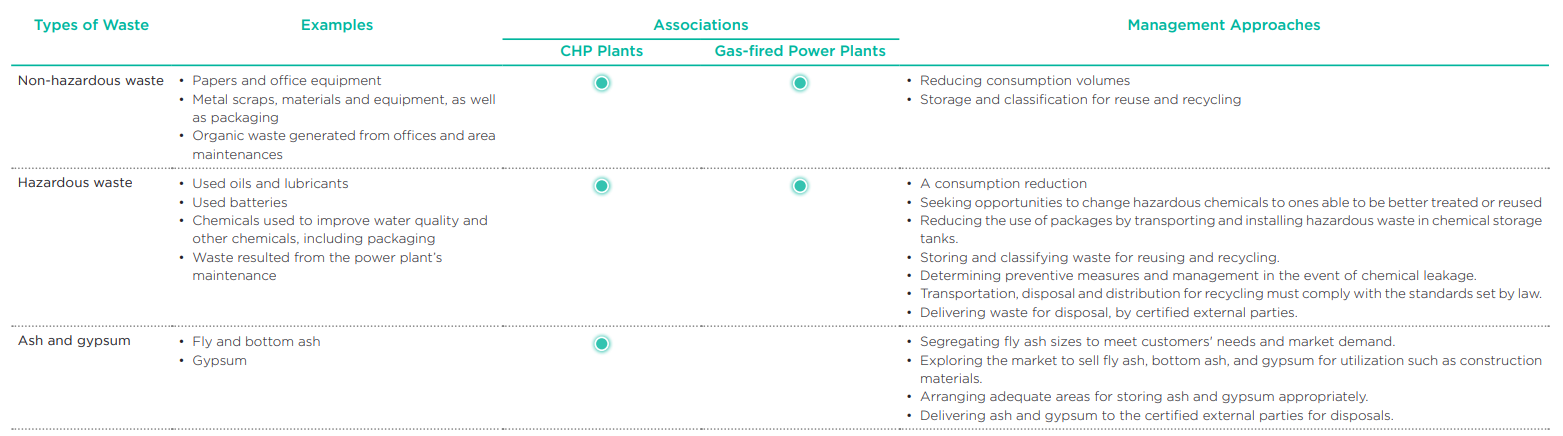

BPP determines the targets to eliminate waste and monitors its performance against the annual target in order to ensure that the operation is carried out in accordance with the best practice and legal requirements of each country. BPP’s waste management approach is based on the 3Rs principle, including:

- Reducing waste at its original sources.

- Reuse

- Recycle

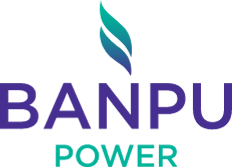

Moreover, BPP promotes the practice guideline for eliminating waste throughout the supply chain. It also classifies waste from its power plants into 3 categories, of which the management approach are concluded as follows:

To assess waste management performance, BPP has collected waste data in accordance with the GRI 306 Waste (2020) standard since the year 2021, by compiling the amount of waste generated and delivered for disposal through weighing and recording data prior to either management or disposals. The amount of waste transported for disposal by outside agencies has been recorded from the receipts. Moreover, agencies permitted by the government are selected to transport and dispose waste so as to ensure that the waste management meet standards according to the requirements of each country and have the least impact on the environment.

Meanwhile, ash and synthetic gypsum – by-products produced by the CHP plants, are included as the non-hazardous waste. These by-product sizes are separated in order to create added values and sell to customers in the construction industry.

Performance

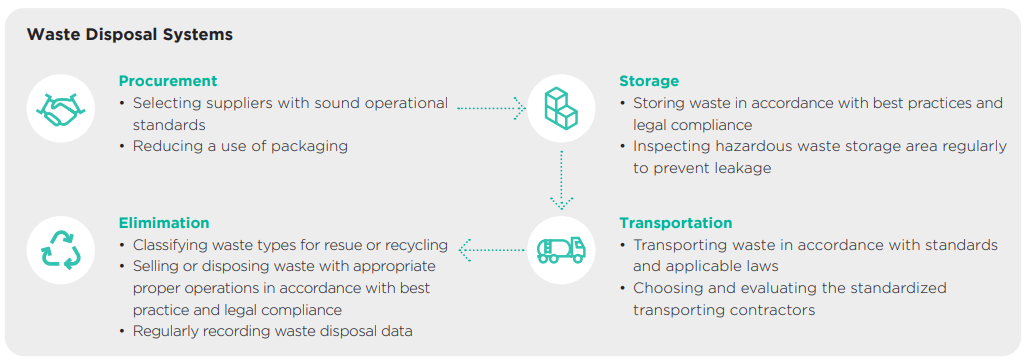

- Hazardous waste directly eliminated was 3 tonnes.

- CHP plants 3 tonnes

- Gas-fired power plant 0 tonne

- 286 tonnes of non-hazardous waste were directly eliminated.

- CHP plants 279 tonnes

- Gas-fired power plant 7 tonnes

- None of hazardous waste to landfill

- None of significant incidents relating to leakage

- Proportion of ash disposed by reuse or recycling was accountable for 100%

- Proportion of gypsum eliminated by reuse or recycling represented 100%

Key Activities and Projects

The Utilization of Industrial Waste Compounded with Coal as Fuels (multisource solid waste compound fuels) at Zouping CHP Plant

The multisource solid waste compound fuels of Zouping CHP Plant is one of the innovative thinking processes to reduce the power plant’s production costs. Zouping CHP Plant studied on how to utilize the solid wastes left over from production processes or from industrial plants with maximum benefits. This initiative was done by surveying industrial wastes in the vicinity where wastes still have calorific values and can be used for boiler’s combustions. The survey found that wastes such as used activated carbons, fly ashes and sludges from the wastewater treatment plants, etc., still have calorific values, and can be used for further combustions.

Zouping CHP Plant conducted a study and carried out a test by using activated carbons with a heat value of about 2,300 kcal/kg from the customer’s sugar factory to mix with coal until the blending ratio does not affect its production capacity, while the air quality released from stacks does not exceed the standard ratio of 10-20%. The experiment found that approximately 2,000-4,000 tonnes of activated carbons can subsidize 600-1,260 tonnes of coal. This initiative project can help reduce the operating costs by CNY 6.4 million per year and decrease dependency on coal consumption in a sustainable way. Moreover, it is another way to help lessen the waste problems from customer’s industries, though, the waste-blending has resulted in a slight decrease of boiler efficiency by about 0.66%.

Wenyu Riverside Cleanup Project to create environmental awareness among employees

Banpu Investment (China) Ltd. or BIC, BPP’s subsidiary in China, joined hands with the Beijing Environmental Protection Foundation (Beijing Watcher) to organize a beach clean-up activity along the Wenyu River in Beijing City on 19 April, 2024, with more than 40 employee volunteers participating. At the event, the employees were divided into 4 groups to collect trash from the beautiful beach area, such as cigarette butts, bottle caps, used plastic bags, etc., and a 28 KG total weight of garbage was collected.

This activity has not only improved the scenery along the river, but it has also helped employees understand the dangers of waste affecting the environment as well as the importance of better protecting river ecosystems. Moreover, it has created participation from employees and local agencies, demonstrating the employees’ social responsibility in every country in which BPP has operated.

Educating employees on waste management

Seeing the importance of employees as a good citizen who can play a key role in conserving resources, Banpu Group invited Mr. Chanat Wuttiwikaikan or Kong Greengreen, a famous content creator to be a guest speaker at the “Safety Day” event, held on 6 November, 2024. An inspiring session on how to protect the earth in a fun and easy way through social media was given by Kong Greengreen, with an aim to provide knowledge to Banpu Group’s employees and educate them about facts regarding waste problems in Thailand. This included telling participating employees how to separate different types of waste and the ways to reduce waste, such as using cloth bags instead of plastic bags, reusing or recycling waste for maximum benefits, etc. At the event, activities involved with correct sorting of waste into different types of trash bins were organized, with over 100 employees attending the event.

Document Download

Waste Management Policy