Significance

In response to a transition to clean energy production in the future, BPP has established the Beyond Quality Megawatts strategy, focusing on creating growth in a low-carbon business by using cutting-edge, clean and environmentally friendly technologies. This includes scaling-up electricity generation from renewable energy, energy technology, and smart energy utilization. In parallel, BPP has put great importance to continuously improve its existing power plants to enhance their power generation stability and availability at the highest level, with high availability factor (AF) and low forced outage

factor (FOF), inclusive of an ability to generate power at maximum efficiency according to the designed value. In addition, BPP has enhanced its ability to compete in the merchant power market in the future, along with delivering electricity and energy in various forms to support smooth economic and social development during the energy transition period.

Management Approach

- Production

BPP puts great emphasis on creating stability and improving the power plants’ efficiency to continuously deliver energy

to customers, by strictly operating productions according to operating procedures. This includes keeping quality maintenances according to specified standards, and determining criteria for supervision, surveillance, audits, risk assessments, as well as regularly monitoring the power plants’ operating performances. It also focuses on supply chain management so that fuels and raw materials can be supplied to the production line according to the action plan set.

BPP has improved the efficiency of CHP plants by increasing their flexibility to consume a variety of fuels, such as industrial waste, low-calorific coal, and biomass, etc., to help reduce production costs during the high coal prices period and to be able to decrease GHG emissions. As for a gas-fired power plant in the United States of America, flexibility is a must to adjust its generation capacity to meet demand in the volatile merchant power market. Moreover, the availability factor must be maintained to be able to supply electricity according to the contract terms and to hedge against risks on selling electricity in the merchant market. This includes increasing the opportunity to make profits during periods of peak demand for electricity or when other power plants have production shortages.

BPP has employed management standards regarding quality, occupational health, safety, and environment in all its CHP plants in order to operate their productions according to the entire operating processes. It also promotes innovation utilization, especially digital technology to be applied to measure various parameters in real time to use such data to create productions readiness and stability.

BPP communicates its production and machinery maintenance plans with customers, suppliers, and contractors earlier to create effective collaboration. Collaboration is very significant in maintaining the power plants’ reliability and AF. The annual machinery maintenance is, therefore, the main activity making the engine’s conditions efficient with a long-service life. As a result, the machines can be operated continuously according to customers’ needs and the plans set.

Machinery maintenance of thermal power plants is carried out in accordance with the maintenance standards set by each power plant. The process includes selecting skilled maintenance contractors and evaluating their performances for improvement. Each year, the power plants will set a schedule for performing their maintenance during the time when there is less energy demand in the area. The aim is to prepare machinery before entering the peak energy demand period. Moreover, all power plants avoid carrying out maintenance simultaneously across all production units since they still must supply power and steam to customers even during their maintenance periods.

- Scaling-up production capacity and investments

BPP has focused on investing in the power plants equipped with “High Efficiency, Low Emission (HELE)” technology, in alignment with the Beyond Quality Megawatts strategy, especially the gas-fired power plants, the renewable energy power plants, the energy technology, and the smart energy utilization. These investment inputs are in the forms of both business operations with direct management control, and joint-venture companies. Prior to investing, each project must be thoroughly examined regarding both risks and return on investments, including assessing the project’s environment, social, and governance (ESG) factors. Additionally, the variants related to ESG issues, such as carbon prices, greenhouse gas (GHG) emissions intensity, etc. are taken into consideration for each investment to ensure that BPP invest in the business able to grow sustainably. Meanwhile, risks are mitigated to an appetite level. Moreover, BPP is looking for opportunities to expand into the integrated energy provider and the low-carbon energy producer to response to increasing demand in clean energy in the future.

Performance

- Commercial operating power generation capacity of 3,584 MW, consisting of:

- 3,174 MWe from thermal power.

- 410 MWe from renewable energy.

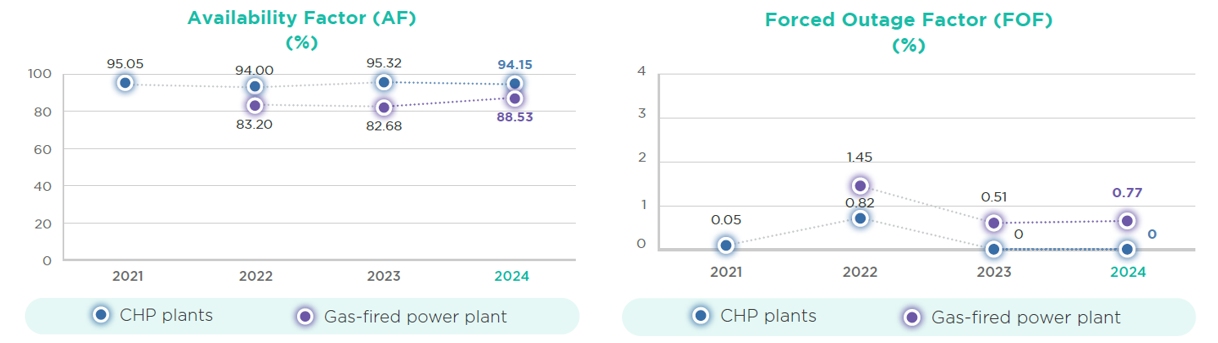

- The AF and FOF of combined heat and power (CHP) plants were 94.15%, and 0%, respectively.

- The AF and FOF of gas-fired power plants were 88.53%, and 0.77%, respectively.